The key to unlocking higher ROI isn’t replacing your farming experience with expensive tech, but amplifying it with targeted, actionable data.

- Start your digital transition with a single, high-impact metric (like fuel consumption per acre) to prove value before expanding your investment.

- Prioritize retrofitting existing legacy equipment over buying new; a significant smart sensor upgrade can be achieved for under $5,000.

Recommendation: To begin, identify your single biggest operational bottleneck or most unpredictable cost—that is your most valuable starting point for data collection.

For generations, the foundation of successful farming has been a deep, almost instinctual understanding of the land. A farm manager can often feel a change in humidity on their skin, judge soil health by its smell, or anticipate a pest outbreak from a subtle shift in the wind. This intuition is powerful, hard-won, and irreplaceable. However, in an era of volatile markets, climate unpredictability, and tightening margins, relying on intuition alone is no longer a strategy—it’s a gamble.

The conversation around “modern farming” is often dominated by futuristic visions of fully autonomous drone fleets and complex AI algorithms, creating the impression that a transition requires a multi-million dollar overhaul. This narrative is not only intimidating for a mid-sized operation; it’s fundamentally misleading. The true power of data-driven agronomy doesn’t lie in replacing the farmer’s brain with a silicon chip. It’s about augmenting that hard-won intuition with objective, measurable evidence.

But what if the key wasn’t a revolutionary leap into “big data,” but a strategic, evolutionary step towards “right data”? The most successful transitions from legacy to data-driven operations don’t start with a blank check for new equipment. They start with a single, well-defined problem and a commitment to measuring what matters. It’s about building a framework that validates your gut feelings, challenges your assumptions, and ultimately scales your expertise across every acre of your operation.

This guide provides a pragmatic roadmap for farm managers looking to modernize. We will deconstruct the process into manageable stages, showing how to digitize workflows without chaos, make smart, incremental tech investments, and leverage data not just for growing crops, but for building a more resilient and profitable business.

The following sections will break down this strategic transition, offering actionable insights and a clear path forward. This article is structured to guide you from understanding the initial risks to implementing a fully integrated, data-informed planning process.

Summary: A Practical Guide to Data-Driven Farm Profitability

- Why Relying Solely on Intuition Risks 30% of Your Yield?

- How to Digitize Your Farm Operations Without disrupting Workflow?

- Manual Logs vs. Digital Dashboards: Which Saves More Time?

- The Tech Investment Mistake That Bankrupts Small Farms

- How to Upgrade Old Tractors with Smart Sensors for Under $5,000?

- Why the Farm Labor Crisis Makes Robots Cheaper than People?

- Why Messy File Names Prevent You From Analyzing Historical Data?

- How to Plan Your Crop Calendar to Avoid Seasonal Bottlenecks?

Why Relying Solely on Intuition Risks 30% of Your Yield?

Your intuition is an asset, but it has limitations. It can’t be in two fields at once, it can’t precisely recall rainfall from three seasons ago, and it struggles to quantify the subtle impact of a new fertilizer blend across hundreds of acres. In today’s agricultural landscape, what you can’t measure, you can’t manage effectively. Relying solely on gut feeling in a data-driven world introduces a significant, unmitigated risk—not just the risk of making a wrong call, but the opportunity cost of missing a right one.

The modern competitive disadvantage isn’t a lack of experience; it’s a lack of connectivity. When your competitors can instantly compare in-field sensor data with satellite imagery to make a variable-rate seeding decision, your “it feels right” approach, however experienced, is fundamentally outmatched. The gap is widening, and it has tangible consequences. For smaller operations, this gap is compounded by infrastructure challenges. As an example, research from Nature Sustainability reveals that only 24-37% of farms under 1 hectare have access to reliable 3G or 4G service, limiting their ability to adopt even basic digital tools.

The risk isn’t just about a potential 30% yield loss in a bad year due to a misjudged planting time or pest issue. It’s about a consistent, year-on-year erosion of your margins by 5-10% due to suboptimal input application, fuel waste, and inefficient labor allocation—small leaks that intuition alone is ill-equipped to detect. Data-augmented intuition doesn’t eliminate experience; it gives it a magnifying glass and a calculator, turning subjective feelings into objective, profit-driven decisions.

How to Digitize Your Farm Operations Without disrupting Workflow?

The thought of “digitizing the farm” often conjures images of chaotic implementations and resistant employees. The secret to a smooth transition is to reject the idea of a farm-wide revolution. Instead, start a targeted evolution, focusing on a single, high-impact metric to build momentum and demonstrate value. This is the “Minimum Viable Metric” (MVM) approach: identify one key performance indicator (KPI) that is both meaningful and relatively easy to track.

This could be fuel consumption per acre, seeding rate accuracy, or time-to-completion for a specific task. The tool can be as simple as a free smartphone app or a shared spreadsheet. The goal is to prove the concept in a low-stakes environment. Crucially, you must identify your most tech-curious employee and empower them to be the “Digital Champion.” This individual becomes the peer-to-peer trainer and internal advocate, making adoption organic rather than a top-down mandate. Their success with the first MVM will be the most powerful case study you have.

This gradual, people-centric approach minimizes disruption and builds a culture of measurement. Once the value of that first tracked metric is clear, the team itself will start suggesting what to measure next. The financial incentive is a powerful motivator; for every dollar invested in the right farm management software, AGRIVI’s analysis shows farms can achieve an $8-12 return, a compelling reason to start the journey.

This process transforms technology from an intimidating unknown into a practical tool used in the context of daily work. The focus shifts from “learning software” to “solving problems,” which is a language every farm operator understands. The initial investment isn’t in technology, but in time and trust.

Your 5-Step Digital Transition Plan

- Select a Metric: Start with one high-impact KPI that can be tracked with existing tools, like fuel consumption per acre using smartphone GPS and logbooks.

- Establish a Baseline: Track this single metric for one full season without making major changes. The goal is to understand your current state accurately.

- Appoint a Champion: Identify your most tech-curious employee as the ‘Digital Champion.’ Make them the owner of the MVM project.

- Facilitate Peer Training: Have this champion lead informal, peer-to-peer training sessions during downtime, showing colleagues how the data is collected and what it means.

- Prove Value, Then Expand: Expand to additional metrics or dedicated software only after you have demonstrated clear, quantifiable value (e.g., “we saved 10% on fuel”) with the first one.

Manual Logs vs. Digital Dashboards: Which Saves More Time?

Every farm runs on information, but how that information is collected, stored, and accessed creates a vast difference in operational efficiency. The debate between a worn-out notebook on the dash and a digital dashboard is not about tradition versus modernity; it’s a stark business calculation of time, accuracy, and decision speed. While manual logs feel tangible and simple, they come with a cascade of hidden time costs.

The time spent deciphering handwriting, manually entering data into a spreadsheet, and correcting inevitable transcription errors is a significant drain on management resources. A digital dashboard, especially one fed by automated sensors, nearly eliminates these issues. What once took days of report compilation at the end of a month can now be visualized in real-time with the tap of a screen. This isn’t a minor convenience; it’s a fundamental shift from reactive problem-solving to proactive management.

Despite these clear advantages, adoption has been gradual. The transition can feel overwhelming, and many operators feel they are “too far behind” to start. However, data shows this is a common position. According to a U.S. Government Accountability Office report on precision agriculture, ” Only 27 percent of U.S. farms or ranches used precision agriculture practices to manage crops or livestock.” This means the vast majority of operations are on the same starting line, and a strategic move toward digital management provides a significant competitive edge.

The table below breaks down the time and cost implications, illustrating just how stark the difference is. The time saved is not idle time; it’s strategic time that can be reinvested into planning, marketing, and managing the business rather than just documenting it.

| Aspect | Manual Logs | Digital Dashboards |

|---|---|---|

| Data Entry | 2-3 hours daily | 15-30 minutes (automated collection) |

| Analysis Time | Days to compile reports | Real-time insights |

| Error Correction | 10-15% of entries need fixes | Near-zero transcription errors |

| ROI Timeline | Hard to measure | 2-5 years payback |

The Tech Investment Mistake That Bankrupts Small Farms

The graveyard of failed farm-tech initiatives is filled with expensive, underutilized hardware. The single most common and catastrophic mistake a mid-sized farm can make is investing in technology before clearly defining the problem it is meant to solve. This “hardware-first” approach is driven by impressive marketing and the allure of a shiny new machine, but it often leads to a solution in search of a problem, draining capital without delivering a measurable return.

Market trends show just how prevalent this trap is. Analysis reveals that the hardware segment holds 55% of the precision farming market share, indicating a massive industry focus on selling physical goods. The mistake is not the technology itself, but the investment sequence. The visionary farm manager doesn’t ask, “Should I buy a drone?” They ask, “What is my biggest source of yield variability or input waste, and what is the most cost-effective tool—be it a drone, a sensor, or a piece of software—to address it?” This is the problem-first investment framework.

By starting with a specific, quantifiable pain point (e.g., “Our fertilizer costs are up 30%,” or “We have persistent water-logging in Field B”), the technology becomes a targeted weapon, not a blunt instrument. The return on investment is clear, and the path to profitability is defined from day one. Anything else is speculation, a high-stakes bet that a mid-sized farm cannot afford to lose.

Case Study: The Problem-First Investment Framework in Action

Many growers experienced the cost of inaction when supply chain shortages caused fertilizer prices to triple in 2022. Growers who used rate controllers for fertilizer management were better prepared for market changes. These operators, who had previously identified “input cost control” as their key problem, were already using prescriptions and sensors to distribute fertilizer with precision. They were experienced with maximizing their input budget while minimizing waste. When the market shifted, they could adjust applications to meet economic constraints by prioritizing their most productive ground, a decision powered by historical field data analysis. This combination of historical data and variable rate application is the one-two punch needed to withstand future instability in the input market.

How to Upgrade Old Tractors with Smart Sensors for Under $5,000?

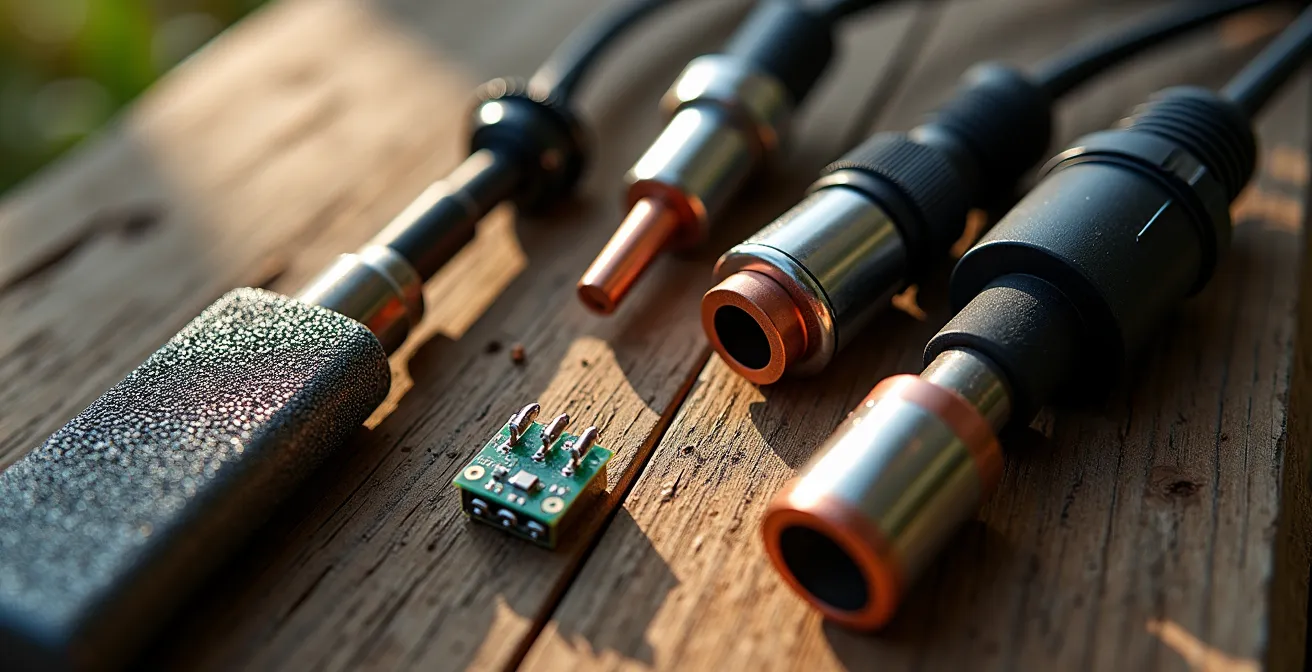

The “hardware-first” mistake often leads to the belief that embracing precision agriculture requires a new fleet of machinery. This is a myth. Your existing, reliable tractors are not liabilities; they are platforms waiting for a strategic, cost-effective upgrade. It’s entirely possible to equip a legacy tractor with powerful smart-sensing and guidance capabilities for under $5,000, unlocking a significant portion of the benefits of a brand-new machine at a fraction of the cost.

The key is a modular, “Good-Better-Best” approach to retrofitting. You don’t need to do everything at once. Start with the component that solves your most immediate problem. For most farms, this is overlap control. A basic GPS receiver and a simple tablet interface can reduce overlap during seeding and spraying, immediately saving on fuel and inputs. From there, you can add rate controllers, seed flow monitors, or full ISOBUS integration as your needs and budget evolve.

This is not a compromise; it’s a smart business decision that generates a remarkably fast return on investment. The focus is on adding the “brains” without replacing the “brawn” you already own and trust. The financial impact can be staggering. For a typical mid-sized operation, even these basic upgrades can yield huge returns. For example, Koenig Equipment’s analysis demonstrates $20,000-34,000 in annual savings on a 1,000-acre farm from simple precision upgrades.

The following guide breaks down a potential upgrade path, showing how you can incrementally build a powerful precision ag system on the back of your existing fleet.

- GOOD ($2,000-$3,000): A basic GPS receiver paired with a mounting bracket and a simple Android tablet for manual guidance. This step alone can reduce input overlap by 10-15%.

- BETTER ($3,500-$4,500): Add a rate controller module to the initial setup. This unlocks the ability to use prescription maps for variable rate seeding and spraying, targeting inputs where they’ll have the most impact.

- BEST ($4,500-$5,000): Integrate a full ISOBUS integration kit with a CAN bus adapter. This allows seamless communication between different brands of implements and the tractor, enabling automated data logging and control.

- Key Consideration: Before any purchase, verify data formats (e.g., Shapefile, GeoJSON) and connectivity standards to ensure future compatibility. Focus on one high-impact sensor first, like a seed flow monitor, which prevents costly skips and doubles.

Why the Farm Labor Crisis Makes Robots Cheaper than People?

The challenge of finding skilled, reliable farm labor is no longer a seasonal headache; it’s a chronic crisis that directly impacts the bottom line. As the available labor pool shrinks and wages rise, the economic equation for automation is fundamentally shifting. Robotics and automated systems are rapidly moving from a futuristic luxury to a pragmatic, cost-competitive alternative to human labor. When you calculate the Total Cost of Ownership (TCO), robots are often cheaper than you think.

A human employee’s cost extends far beyond their salary. It includes insurance, payroll taxes, training, and the difficult-to-quantify costs of recruitment, management, and potential human error. A robotic system, whether purchased outright or leased as a “Robotics-as-a-Service” (RaaS) model, has a predictable, transparent cost structure. The value proposition is particularly strong for highly repetitive tasks where precision is key.

The connection between labor scarcity and technology adoption is clear. As stated in a recent market analysis, “Adoption of GNSS auto-steering has reached 70% on farms over 1,000 ha versus 52% on midsize holdings. Labor shortages heighten the value proposition by substituting scarce operators with robotics that maintain perfectly straight rows.” This isn’t about replacing people wholesale; it’s about deploying your valuable human team members to higher-level tasks that require judgment and problem-solving, while automating the repetitive work that can be done more consistently and cheaply by a machine.

The following table provides a simplified TCO analysis, illustrating how the long-term costs compare. For a forward-thinking farm manager, understanding this math is no longer optional.

| Cost Factor | Human Labor (Annual) | Robotics-as-a-Service |

|---|---|---|

| Base Cost | $35,000 salary | Pay per acre/hour |

| Hidden Costs | +$15,000 (insurance, tax, training) | None (included) |

| Error Impact | 5-10% yield loss potential | < 2% variance |

| 5-Year TCO | $250,000+ | $150,000 (estimated) |

Why Messy File Names Prevent You From Analyzing Historical Data?

You can have the most advanced sensors and the most powerful analytics software in the world, but if your yield map from last spring is named “Field_B_yield_final_2.shp” and your soil sample data is in a folder called “Misc June,” you have collected data, but you have zero intelligence. This is the unglamorous but absolutely critical foundation of data-driven agronomy: disciplined data management.

Messy, inconsistent file names are the silent killer of ROI. They make year-over-year comparisons nearly impossible, corrupt historical analysis, and ensure that valuable insights remain locked away in a digital mess. To track trends, correlate weather patterns with yield, and truly understand the long-term impact of your decisions, you need a standardized system. Without it, you are effectively starting from scratch every season, unable to learn from your past successes and failures.

The solution is not complex or expensive. It’s a simple, upfront commitment to a naming convention. A standardized format ensures that every piece of data—from soil tests and planting maps to yield data and drone imagery—is consistent, searchable, and, most importantly, analyzable. This discipline transforms a chaotic collection of files into a strategic business asset, a digital library of your farm’s unique history that grows more valuable with each passing season.

Implementing a system is straightforward. It requires a simple template and the discipline to stick to it. This small investment of time pays massive dividends by enabling the very analysis that drives profitability.

Checklist: Your Farm Data Naming Convention

- Define the Standard Format: Establish a clear, universal format. A robust example is: YYYY-MM-DD_[FieldID]_[Activity]_[Variable]_[Operator].csv.

- Create the Data Dictionary: Document what each code means in a central file (e.g., A01 = North Field, A02 = River Field; Plant = Planting, Fert = Fertilizing).

- Structure Your Folders: Organize your computer files logically. A good hierarchy is Year > Season > Field > Activity Type.

- Implement the 3-2-1 Backup Rule: Always maintain at least three copies of your data: your working copy, a local backup (on a separate hard drive), and a cloud backup.

- Use Version Control: When a file is revised, add a version number (e.g., _v2, _v3) rather than overwriting the original. This prevents irreversible mistakes.

Key Takeaways

- The ultimate goal is not to replace the farmer but to create “data-augmented intuition,” using objective evidence to refine and validate expert judgment.

- A successful digital transition starts small. Focus on one “Minimum Viable Metric” to build momentum, secure buy-in from your team, and prove ROI before expanding.

- Disciplined data management, starting with a standardized file naming convention, is the non-negotiable foundation for any long-term analysis and strategic planning.

How to Plan Your Crop Calendar to Avoid Seasonal Bottlenecks?

The ultimate goal of data collection is not to create beautiful charts; it’s to make better, more profitable business decisions. The pinnacle of data-driven agronomy is when you move from using data for tactical, in-season adjustments to using it for strategic, multi-year planning. This is where you can use your clean, historical data to design a crop calendar that anticipates and mitigates seasonal bottlenecks before they occur.

An operational bottleneck is any point in your process where a constraint limits the entire system’s output. In farming, this could be a shortage of labor during harvest, a single piece of equipment being required in two fields at once, or a planting schedule that exposes a critical growth stage to predictable weather risks. By analyzing several seasons of data on task completion times, equipment usage, and yield variance, you can identify these hidden chokepoints. A well-planned crop calendar, informed by data, staggers activities, optimizes equipment routing, and aligns labor needs with availability.

This transforms the farm from a series of reactive tasks into a smoothly functioning, proactive operation. It allows you to ask and answer high-level business questions: “If we plant Field C with an earlier-maturing variety, will that free up the combine in time to harvest Field A at its peak?” or “Does the fuel cost of tilling Field D outweigh the marginal yield benefit?” This is the true ROI of data-driven agronomy: the ability to run your farm like the sophisticated, multi-million dollar business that it is.

Case Study: Integrating Data for Measurable ROI

Farms that successfully integrate data analysis into their core planning see profound results. Efficiency and ROI metrics show reduced fertilizer and pesticide use (often by 20-50%) and significant water savings (20-40%), leading to better yield stability even in volatile conditions. The key is tracking clear KPIs that link actions to outcomes, such as input-use efficiency (kg of fertilizer per ton of yield), yield-per-hectare variance across different management zones, and profitability per labor-hour to accurately track the impact of automation.

By moving from intuition alone to data-augmented intuition, you are not losing your connection to the land; you are building a more resilient, predictable, and profitable business upon it. The first step is to choose your first metric and begin the journey today.

Frequently Asked Questions on Data-Driven Agronomy

How much can precision planning improve yields?

Data consistently shows a positive impact. Approximately 75% of farmers who adopt and use precision farming technologies and methods report higher crop yields as a direct result.

What’s the typical payback period for calendar optimization tools?

While specific payback varies by operation, the market for precision agriculture is forecast to grow at a Compound Annual Growth Rate (CAGR) of 12% to 15%. This rapid market expansion suggests that farmers are realizing value and ROI quickly from these investments.

Which planning application grows fastest?

Currently, irrigation management is the fastest-expanding application area within precision agriculture. The ability to apply water with high precision based on real-time soil moisture data delivers immediate and significant savings, driving its rapid adoption.