Designing for animal welfare is not an operational expense but a strategic investment in systemic risk mitigation and measurable efficiency.

- Engineered air quality and ergonomic flooring directly reduce mortality and injury, lowering veterinary costs.

- Biosecure traffic flow and automated systems address disease threats and the escalating farm labor crisis.

Recommendation: Prioritize a modular structural design that integrates biosecurity, labor efficiency, and future automation from the ground up to maximize long-term return on investment.

For farm owners, the rising tide of animal welfare regulations can feel like a cascade of compliance costs and operational hurdles. The conventional approach often involves patching existing infrastructure or reluctantly adding new features to meet a checklist. This reactive mindset treats welfare as a burden, a separate layer of expense that detracts from the core business of production. Common advice to simply “provide more space” or “keep things clean” fails to address the underlying structural inefficiencies that create problems in the first place.

But what if the entire framework is flawed? What if the key to meeting new standards isn’t about adding costs, but about fundamentally re-engineering the facility for performance? This guide adopts the perspective of a livestock building engineer, reframing animal welfare as a direct outcome of smart, ergonomic design. We will explore how every structural choice—from ventilation dynamics to flooring texture—can be designed as an integrated system to mitigate specific production risks like disease, injury, and reproductive failure.

This approach moves beyond mere compliance. It transforms the breeding facility from a simple container into a high-performance asset engineered for animal health, labor efficiency, and long-term profitability. By focusing on the physics of air, the ergonomics of movement, and the logic of biosecure flow, you can build a facility that not only meets today’s standards but is also resilient and adaptable for the challenges of tomorrow.

This article provides a detailed examination of the critical engineering principles that underpin a modern, high-welfare breeding facility. We will dissect key structural systems to demonstrate how intelligent design choices directly translate into improved animal health and enhanced operational productivity.

Summary: Designing High-Performance Breeding Facilities

- Why Poor Ventilation Kills More Calves Than Cold Weather?

- How to Select Slat Flooring That Prevents Hoof Injuries?

- Group Housing or Stalls: Which Improves Sow Longevity?

- The Manure Pit Danger That Threatens Animal Lungs

- How to Program Light Cycles to Stimulate Reproduction?

- How to Set Up a Quarantine Zone Separate from the Main Herd?

- Why the Farm Labor Crisis Makes Robots Cheaper than People?

- How to Manage Vaccination Schedules for a 200-Head Herd?

Why Poor Ventilation Kills More Calves Than Cold Weather?

While cold is a visible stressor, the invisible threat of poor air quality is a far more significant driver of calf mortality. Inadequate ventilation traps airborne pathogens, moisture, and toxic gases like ammonia at animal level, creating a perfect storm for respiratory disease. Calves, with their developing immune systems, are particularly vulnerable. When air becomes stagnant, the concentration of bacteria and viruses multiplies, leading to outbreaks of pneumonia that can devastate a young herd. Furthermore, high humidity in a poorly ventilated barn makes bedding damp, which compromises the calf’s ability to maintain body temperature and increases susceptibility to illness.

The danger is not just disease; it’s also heat stress. It is a common misconception that ventilation is only for cooling in summer. However, research from Frontiers in Veterinary Science shows the mortality risk in calves doubles when the average daily temperature exceeds 22°C. A properly engineered ventilation system works year-round to exhaust stale, humid air and introduce fresh, clean air without creating harmful drafts. This constant air exchange is a non-negotiable engineering requirement for diluting pathogen loads and managing the microclimate. Treating ventilation as a foundational utility, not an optional extra, is the first step in designing a facility that actively promotes animal health rather than passively housing them.

Your Action Plan: Critical Steps for Optimal Calf Barn Ventilation

- Design for a minimum of 4 air exchanges per hour during cold weather, using either natural or mechanical ventilation systems to ensure constant air renewal.

- Conduct smoke bomb testing to visually verify airflow patterns; the smoke should clear from the building within 60 seconds for adequate air exchange.

- Monitor ammonia levels at calf height using colorimetric detection tubes, with the goal of keeping concentrations below 5 ppm.

- Position ridge outlets at a minimum of 0.04m² per calf and ensure the total inlet area is double the outlet size (0.08m² per calf) to create effective stack effect ventilation.

- Consider positive-pressure tube ventilation (PPTV) systems for consistent, draft-free delivery of fresh air directly into the calves’ resting zone.

How to Select Slat Flooring That Prevents Hoof Injuries?

The floor is the single most important interface between the animal and the building. A poorly chosen or designed flooring system is a primary cause of hoof injuries, lameness, and joint stress, leading to significant economic losses through decreased productivity, increased culling rates, and higher veterinary bills. Traditional concrete, while durable, is hard and unforgiving, contributing to lesions and discomfort. The goal of ergonomic flooring design is to provide a surface that balances three critical factors: traction, comfort, and cleanliness. A surface that is too smooth can cause slips and falls, while one that is too abrasive can wear down hooves. The ideal floor must provide enough grip for confident movement without causing physical damage.

Modern slat flooring systems are engineered to address this challenge. Materials like rubber-coated concrete offer a superior solution by combining the durability of concrete with a cushioned, non-slip surface. This ergonomic approach reduces impact stress on joints and provides better thermal insulation than bare concrete. Furthermore, the design of the slats themselves—their width, the gap between them, and the edge profile—is critical. Sharp edges can cause foot injuries, while incorrect gap spacing can lead to hoof entrapment. Selecting flooring should not be a decision based on initial cost alone, but an investment in an engineered system designed for long-term animal health and mobility.

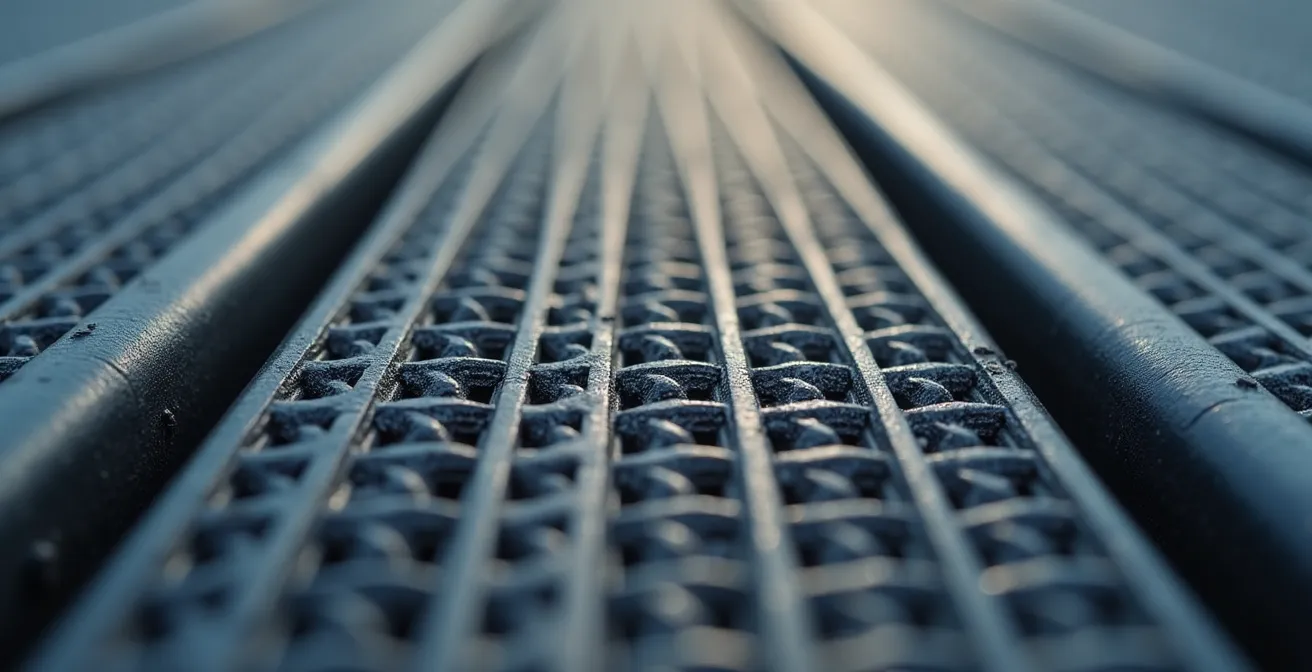

The texture of the flooring surface is a key design element. As shown in the image, modern rubber coatings feature intricate patterns engineered to maximize grip while remaining easy to clean, preventing the buildup of bacteria that can lead to foot infections. This attention to micro-surface detail is a hallmark of an ergonomically designed facility.

This comparative table highlights the trade-offs between different flooring materials, making it clear why a hybrid solution often provides the best balance of performance and long-term value.

| Flooring Type | Durability | Animal Comfort | Cleaning Ease | Cost |

|---|---|---|---|---|

| Concrete | Excellent (25+ years) | Poor (requires mats) | Excellent | High initial |

| Rubber Coated | Good (10-15 years) | Excellent | Good | Medium |

| Slatted | Good (15-20 years) | Fair | Self-cleaning | High initial |

| Deep Bedding | Requires replacement | Excellent | Labor intensive | Low initial |

Group Housing or Stalls: Which Improves Sow Longevity?

The debate between individual gestation stalls and group housing systems is central to modern sow management and welfare standards. While stalls offer control over individual feeding and prevent aggression, they severely restrict movement and natural social behaviors. This restriction is increasingly linked to leg weakness, joint problems, and stress, which can shorten a sow’s productive lifespan. Group housing, when properly designed, allows for freedom of movement and social interaction, which are two of the globally recognized “Five Freedoms” of animal welfare. This freedom contributes to better physical conditioning, stronger legs, and improved overall fitness.

However, simply placing sows in a group is not a guaranteed solution. Success is entirely dependent on engineering the environment to mitigate the system’s inherent risks, primarily aggression and competition for food. A well-designed group housing system incorporates features like protected feeding stalls that allow individual access to rations, non-aggressive pen layouts with escape routes, and sufficient space to reduce social pressure. According to Cornell University’s veterinary guidelines, animal density should not exceed 10% over the facility’s designed capacity to maintain optimal welfare conditions. This prevents the overcrowding that fuels conflict.

Case Study: Designing for the Five Freedoms

Research from Penn State Extension on dairy facilities designed around the Five Freedoms framework provides valuable insights applicable to sow housing. The study documented that facilities providing sufficient space, proper amenities, and opportunities for companionship resulted in more natural behavior expression and lower stress indicators. The most successful designs combined the benefits of group housing for socialization with dedicated individual areas for feeding or veterinary treatment, proving that welfare and management efficiency are not mutually exclusive when engineered correctly.

Ultimately, a well-engineered group housing system can lead to improved sow longevity by promoting better physical health and reducing chronic stress. The initial investment in a more complex design pays dividends through lower replacement rates and more resilient animals.

The Manure Pit Danger That Threatens Animal Lungs

The manure pit beneath a slatted floor is more than a storage tank; it’s a bioreactor that constantly produces a cocktail of hazardous gases, including ammonia (NH3), hydrogen sulfide (H2S), carbon dioxide (CO2), and methane (CH4). Of these, ammonia is a primary threat to respiratory health. As a caustic gas, it irritates the sensitive mucosal linings of the lungs, making animals more susceptible to bacterial and viral infections like pneumonia. Chronic exposure, even at low levels, leads to persistent inflammation and reduced lung function. For farm owners, this translates directly to higher treatment costs, lower feed conversion efficiency, and increased mortality.

Engineering a solution requires treating pit gases as a systemic atmospheric problem, not an unavoidable nuisance. The objective is to prevent gas from accumulating in the animals’ breathing zone. As University of Wisconsin dairy research confirms, ammonia levels above 10 ppm can negatively affect calf health, with ideal conditions remaining below 5 ppm. This cannot be achieved with overhead ventilation alone, which often fails to pull heavy gases up from the floor. Modern designs incorporate under-floor pit ventilation systems with dedicated exhausts that continuously pull gases out of the pit before they can rise into the animal space. Other effective strategies include shallow-pit recharge systems that are flushed frequently, preventing the long-term anaerobic decomposition that generates the most dangerous gases.

This technical illustration demonstrates the concept of a multi-layered ventilation system. While natural stack effect ventilation manages heat and humidity in the upper space, a separate, dedicated system is engineered at the floor level to actively manage and exhaust harmful gases from the manure pit. This dual approach is critical for maintaining healthy air quality throughout the entire facility profile.

How to Program Light Cycles to Stimulate Reproduction?

Lighting in a breeding facility is not just for human visibility; it’s a powerful biological tool that can be programmed to regulate and stimulate animal reproductive cycles. Many livestock species, including swine and cattle, have hormonal cycles that are influenced by photoperiod—the length of daylight. By using artificial lighting to manipulate the perceived length of the day, producers can encourage animals to come into estrus more consistently, improve conception rates, and manage breeding schedules more effectively. This goes far beyond simply installing a few bulbs; it requires a strategic, engineered lighting plan.

An effective lighting program considers three key elements: intensity, duration, and spectrum. Intensity, measured in lux, must be bright enough to trigger the desired physiological response; a minimum of 200-250 lux at eye level is a common target. Duration involves providing a long day photoperiod, typically 16 to 18 hours of light, to stimulate reproductive hormones. Finally, the light spectrum, or color temperature, can also play a role, with full-spectrum lighting that mimics natural daylight often being the most effective. Integrating these systems with programmable controllers allows for automated dawn/dusk transitions, which reduce stress compared to the abrupt on/off of simple timers.

The impact of a poor light environment, and environmental stress in general, on production is well-documented. For instance, research highlighted by Cornell Cooperative Extension demonstrates that cows spending more than 3.5 hours daily in dimly lit, stressful holding areas can show a significant drop in milk production. While this relates to dairy, the principle is universal: a poorly designed environment creates stress that costs money. A properly engineered lighting system is a low-cost, high-impact tool for optimizing the biological performance of the herd, turning a basic utility into a reproductive management asset.

How to Set Up a Quarantine Zone Separate from the Main Herd?

A quarantine zone is the single most important structural defense against a catastrophic disease outbreak. It is not just a spare pen; it is an engineered biosecurity system designed to completely isolate new or sick animals from the main herd. The primary goal is to create an “air gap” that prevents the transmission of pathogens via direct contact, aerosols, or contaminated equipment. A properly designed quarantine facility must be physically separate from the main barns, ideally with its own dedicated entrance, equipment, and waste management system. It should also be positioned so that the prevailing winds and water runoff flow away from the main facility, not towards it.

The internal design is guided by the principle of “architectural flow.” As documented in facility design principles from the National Institutes of Health, successful biosecure designs create a one-way flow of animals and personnel from “clean” (main herd) to “dirty” (quarantine) zones, with mandatory sanitation checkpoints in between. Staff should never move from the quarantine area back to the main herd without a complete change of clothes and disinfection. An even more robust approach is the two-stage quarantine system, which provides an additional layer of security by separating initial isolation from the acclimatization phase, further reducing the risk of introducing a latent disease into the herd.

This table compares the single-stage and two-stage systems, illustrating how the higher initial investment in a two-stage design translates into superior risk mitigation—a critical ROI calculation for any operation.

| Aspect | Single-Stage | Two-Stage System |

|---|---|---|

| Initial Investment | Lower | Higher (30-40% more) |

| Disease Detection Rate | Standard | Enhanced (+25%) |

| Acclimatization Period | Combined with quarantine | Dedicated secondary phase |

| Space Requirements | Baseline | 1.5x baseline |

| Risk Mitigation | Basic | Superior |

Why the Farm Labor Crisis Makes Robots Cheaper than People?

The agricultural sector is facing a deepening labor crisis, characterized by rising wages, worker shortages, and high turnover rates. In this economic environment, the calculus for automation has fundamentally shifted. Robotic systems, once seen as a luxury, are increasingly becoming a more predictable and cost-effective long-term solution than human labor. The cost of a robotic feeding or cleaning system is a fixed capital investment, whereas labor costs are variable and consistently trend upward. When you factor in the costs of recruitment, training, benefits, and the productivity losses associated with staff shortages, the return on investment for automation becomes compellingly short.

However, retrofitting automation into a facility not designed for it is expensive and inefficient. The key to leveraging this technology cost-effectively is to design the building to be “robot-ready” from the start. This involves an approach of modular automation, where the building’s infrastructure is pre-planned to accommodate future robotic integration. This means designing alleys with sufficient width and turning radii for automated feeders, installing the necessary power and network conduits in the walls and floors, and ensuring structural supports are placed to allow for future robotic arms or cleaning systems.

Case Study: Phased Automation Through Modular Design

The American Grassfed Association has highlighted the success of farms implementing this strategy. By building facilities with the core infrastructure for automation, owners can make incremental investments as the ROI is proven. A common approach is to begin with automated feeding and water systems, which offer a quick return by reducing daily labor. The next phase might be the installation of robotic manure scrapers. Full integration can be achieved over a 3-5 year period, allowing capital expenditure to be spread out while continuously reducing reliance on manual labor. This forward-thinking structural design turns the building itself into a platform for future efficiency.

This strategic approach to building design transforms a facility from a static structure into an adaptable system, ensuring that the farm is not only efficient today but also prepared for the economic and labor realities of the next decade.

Key Takeaways

- Animal welfare is an engineering outcome, not a moral accessory. Every design choice has a direct impact on health and productivity.

- Systemic risks like respiratory disease and hoof injuries are mitigated through structural solutions like engineered ventilation and ergonomic flooring, not just treatment.

- Future-proofing a facility means designing for biosecurity (quarantine zones) and automation readiness (modular design) to address disease and labor challenges head-on.

How to Manage Vaccination Schedules for a 200-Head Herd?

Managing the health of a 200-head herd requires a systematic approach, and vaccination is a cornerstone of that strategy. However, the logistical challenge of processing hundreds of animals efficiently, safely, and accurately can be a major bottleneck. A poorly designed facility turns vaccination day into a high-stress event for both animals and staff, leading to missed animals, incorrect dosages, and potential injuries. This is where ergonomic engineering of animal flow becomes critical. The facility’s layout should be designed to make routine health management tasks like vaccination as seamless and low-stress as possible.

A smart sorting system is the heart of an efficient processing operation. This begins with wide processing alleys—a minimum of 14-16 feet—that allow animals to move smoothly without the crowding that causes panic. Within these alleys, automated sorting gates, integrated with RFID/EID readers, can automatically identify and separate animals due for specific treatments based on their electronic records. This eliminates the manual guesswork and physical effort of cutting animals out of a group. This system should lead to a dedicated, well-lit veterinary room with climate-controlled vaccine storage, ensuring product efficacy and providing a safe, clean environment for administration.

This proactive design approach is part of a holistic view of herd health. While vaccines are a vital tool, their effectiveness is supported or undermined by the environment. For example, research in equestrian architecture indicates that barns with proper ventilation systems see 40% fewer respiratory issues. This highlights that a well-designed building reduces the overall disease pressure on the herd, making vaccination programs more effective. The structure itself becomes an active participant in the health management protocol, saving labor, reducing stress, and ultimately producing better outcomes.

By shifting the perspective from simple housing to performance-based engineering, farm owners can meet and exceed new welfare standards not as a matter of compliance, but as a strategic path to creating a more resilient, productive, and profitable operation.